— COMPANY

Cornell University

— ROLE

Product Designer

— DATE

Spring 2020

As part of an individual design project for my Rapid Prototyping class at Cornell University, I was tasked with creating original designs in AutoCAD for COVID-19 PPE equipment that could be 3D printed for medical workers.

Problem

Medical workers need enough PPE to treat patients, but there’s limited availability due to manufacturing capacity and high demand because of COVID-related hospitalizations.

Opportunity

Creating reusable 3D printed medical-grade face shields and face masks will help doctors treat patients efficiently and effectively while saving lives.

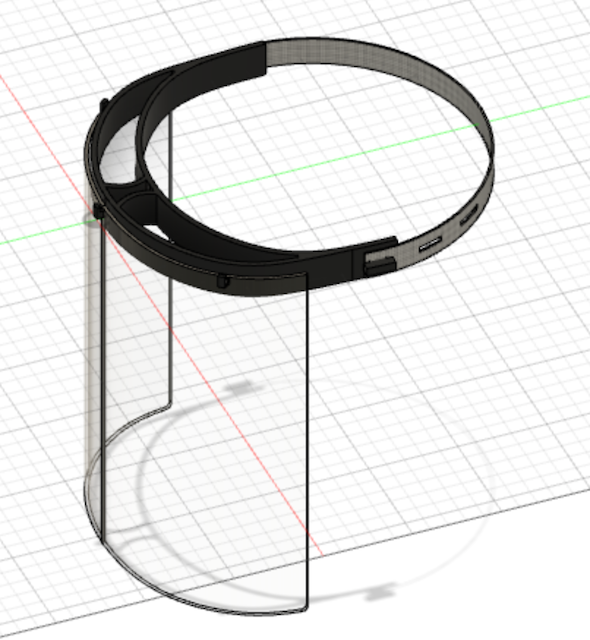

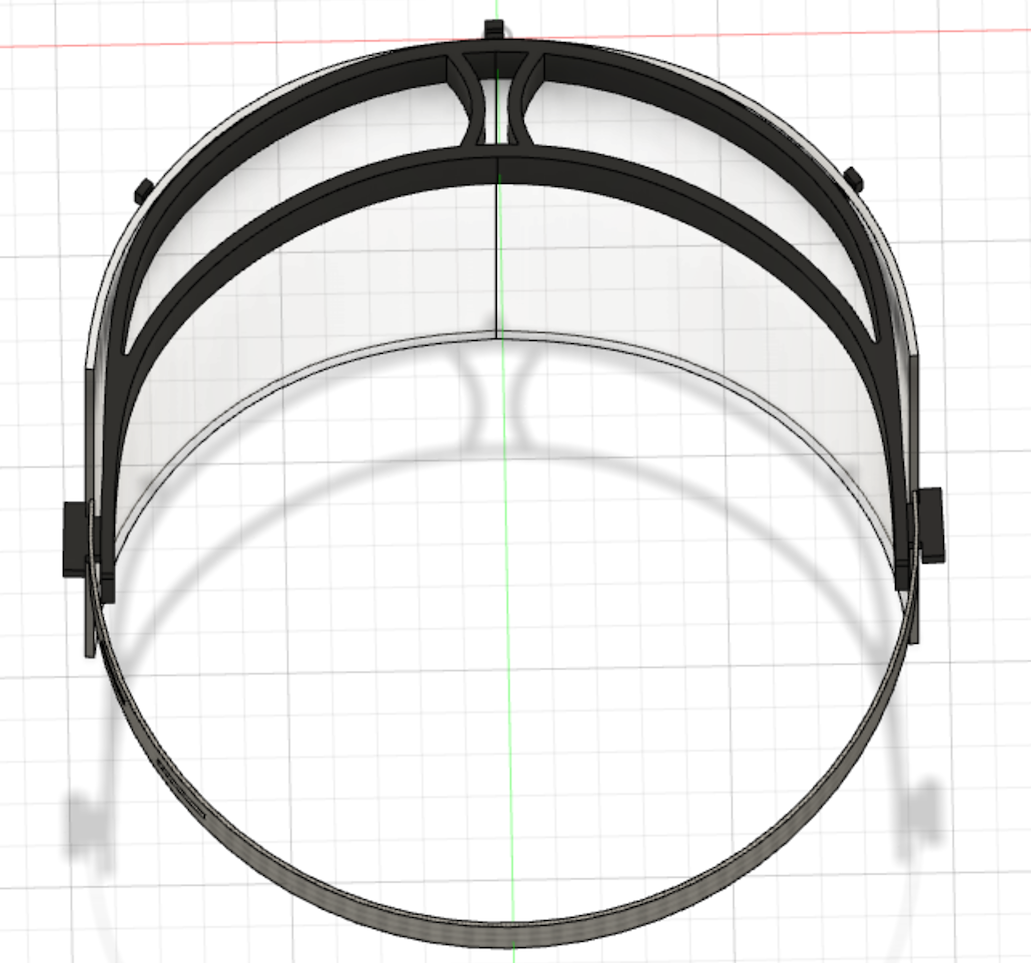

Face Shield Final Design

- Making room for the user’s nose and glasses (if they wear them). The farthest headband away from the head is to allow for space between the acrylic shield and the person’s face

- Fast Printing Time. Connecting both sides of headband with a simple pronged support was meant to be as thin as possible while still providing support because it’s quicker to print two simple skinny pieces instead of having the entire area filled like a traditional sports visor. If you’re printing hundreds or thousands of visors, printing time really adds up.

- Connecting the plastic shield to the visor. The front part of the visor has 3 little pieces that stick out so you can clip on the face shield and keep it in place. The shield was designed to be removable to it could be easily cleaned and reused.

- Adjustable elastic band. In order to accommodate for different sized heads, there is an adjustable elastic band. The band has several different holes along one side that the user can pick from according to what fits them. The elastic band is fitted onto 2 pieces that are on each side of the visor. The decision to use an elastic band instead of having a 3D plastic print was to save print time and allow for comfort when wearing.

- Reusable Materials that are easily cleaned.

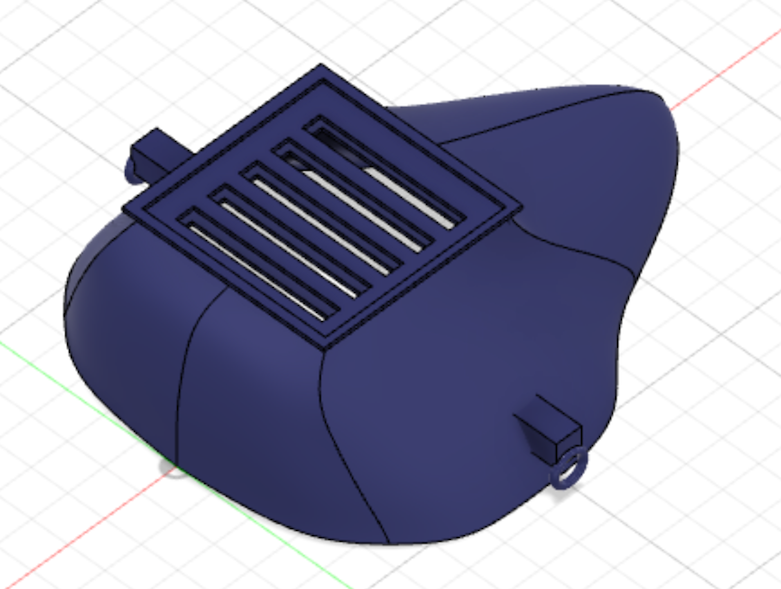

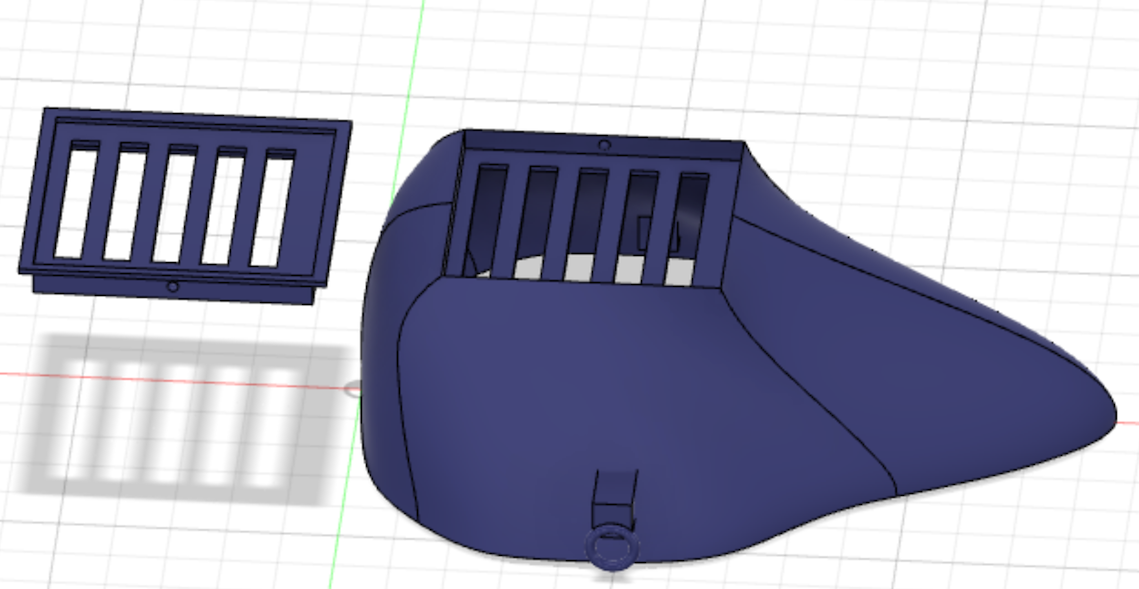

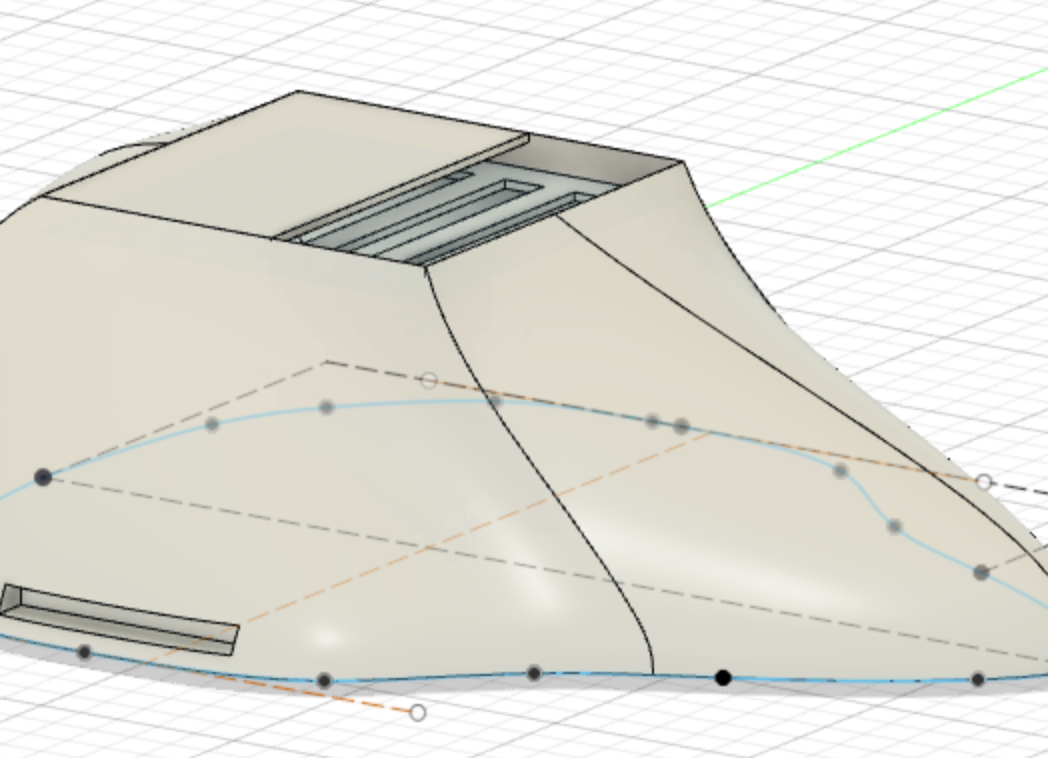

Face Mask Final Design

- Removable Grate for Filters. Each medical worker only needs one and just needs to have filters for each use.

- Slits in Grate. Both the grate and the filter holder have holes in them to allow for breathing since the mask is made of plastic. The filter that can be placed in the mask will work to stop particles for entering the mask.

- Slight Lip Around the Grate. To allow for easy removal.

- Click in Grate. In order for the grate to click in, I designed it with small holes to click into place with the small spheres that are on the filter container.

- Attachment Hooks on Each Side. In order to attach the face mask to the face, I decided to put in two extruding pieces where the cheeks would be and put in a loop. This loop is to attach string or a rubber band that would go around the ears of the user.

Face Mask Design Iteration #1

Non Removable Grate

Further Thought

It became apparent that the user might misplace the filter, which could leak and infect the user. Additionally, it might be hard to place the filter in if the top part material was too sturdy.

Conclusion

Unfortunately, because our school went online during the second half of the semester, we weren’t able to actually 3D print our designs. However, it was awesome to design for real-world problems and learn how to use AutoCAD for 3D printing. If my designs were implemented, they would be an efficient way to protect medical workers due to the nature of the designs such as being reusable, easily cleanable, adjustable, and having a quick printing speed so that many can be printed in bulk. Due to the shortage of supplies for PPE, it would be more efficient to have a reusable option such as 3D printable plastic designs like these instead of wearing a new mask every time.

Future Work

For the face shield, I spoke with a medical worker after I did this case study and he mentioned that they often sweat a lot and it would be helpful to have a piece of foam on the inside of the headband to absorb it. This would stop sweat from getting into medical workers’ eyes.

Additionally, fit-tests would need to be performed on both the visor and the mask in order to ensure that there aren’t any gaps for germs to get into.